Infrastructure | 14. November 2022

RhB relies on standardization with low-voltage solutions from ABB

The Rhaetian Railway maintains a comprehensive infrastructure in Switzerland’s largest canton. The railway follows a standardization strategy using circuit breakers and installation equipment from ABB for its low-voltage power supply to maximize availability and boost efficiency – particularly in service and maintenance.

The Rhaetian Railway (RhB) and ABB have been partners for over 100 years. BBC and MFO supplied the electrical equipment for the first electric locomotives as early as 1913. These predecessors to ABB were the leaders in traction equipment for locomotives, just as ABB leads the way today with the electronic traction converters that power RhB’s new Capricorn multiple units.

While ABB drive technology propels the RhB trains, our company’s electrification solutions ensure the efficient distribution of power in the Rhaetian Railway’s extensive infrastructure.

RhB infrastructure sites spread across the entire canton

The rail network is 385 kilometers long and leads through over 100 tunnels. RhB operates workshops and service buildings for maintenance purposes. The infrastructure base in Landquart was commissioned in 2020 and is a central hub for around 100 employees working in the infrastructure department. Additional sites are located in places like Chur, Davos, Klosters, Ilanz, Thusis, Bergün, Poschiavo, Pontresina, Samedan and Zernez Bergün, Ilanz and Poschiavo. Their employees build and maintain the track with rails and switches, power and catenary systems, safety equipment and all low-voltage and telecommunications systems that serve rail operations and ensure that the lines and stations can be used safely and comfortably during all seasons and in any weather conditions.

Early adoption of ABB’s SMISSLINE

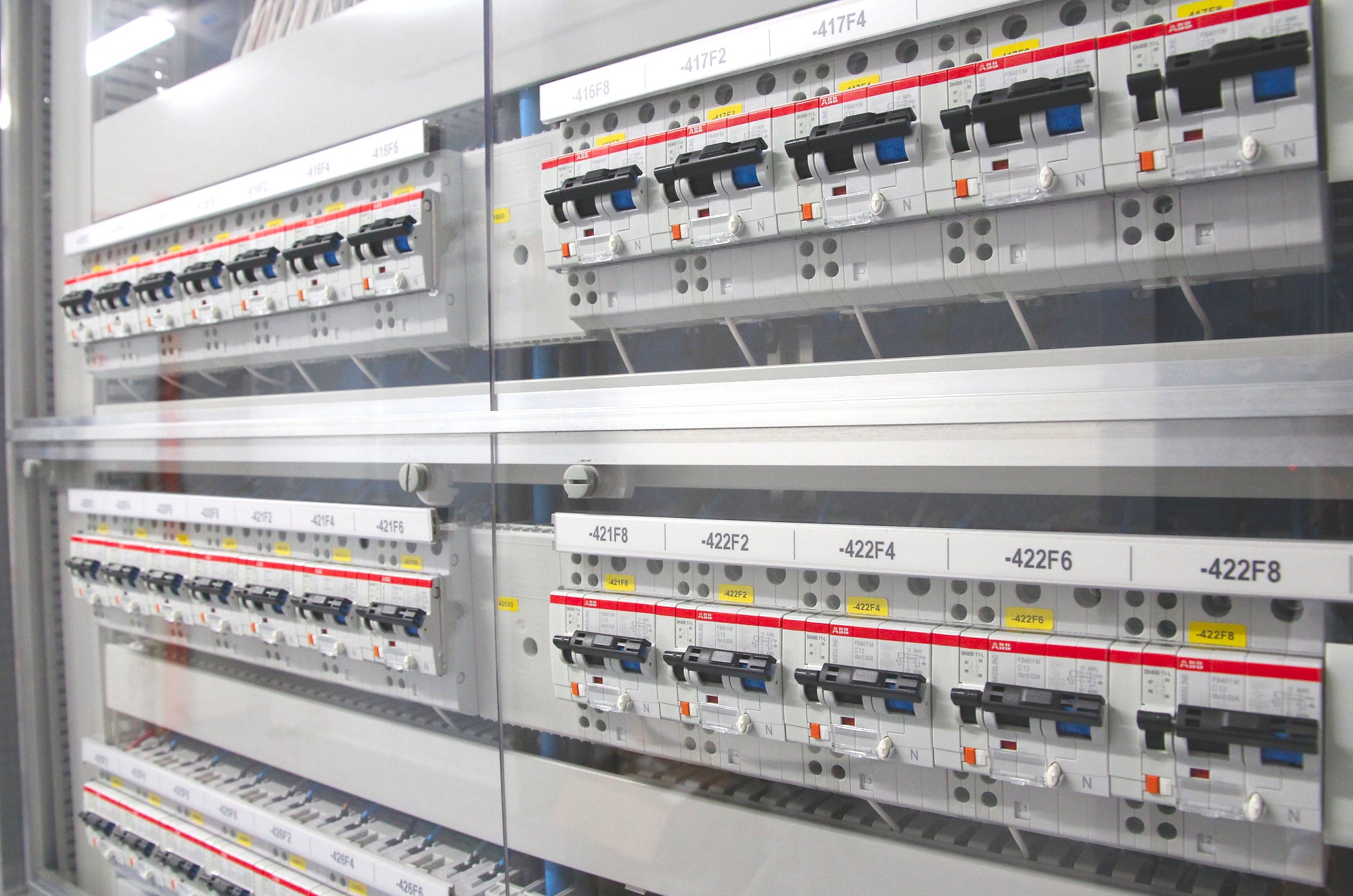

All of these systems require a reliable supply of power. “We’ve used the SMISSLINE plug-in distribution system for many years and have defined it in our material specifications for electrical designers, installation technicians and switchgears,” explains RhB’s Head of Low Voltage/Telecom, Maurus Cotti.

RhB was also one of the early adopters of the SMISSLINE TP Power Bar introduced in 2018 for currents of up to 250 amperes – this was especially true for the traction power supply, where networks have a frequency of 16 2/3 hertz instead of the standard 50 hertz supply networks.

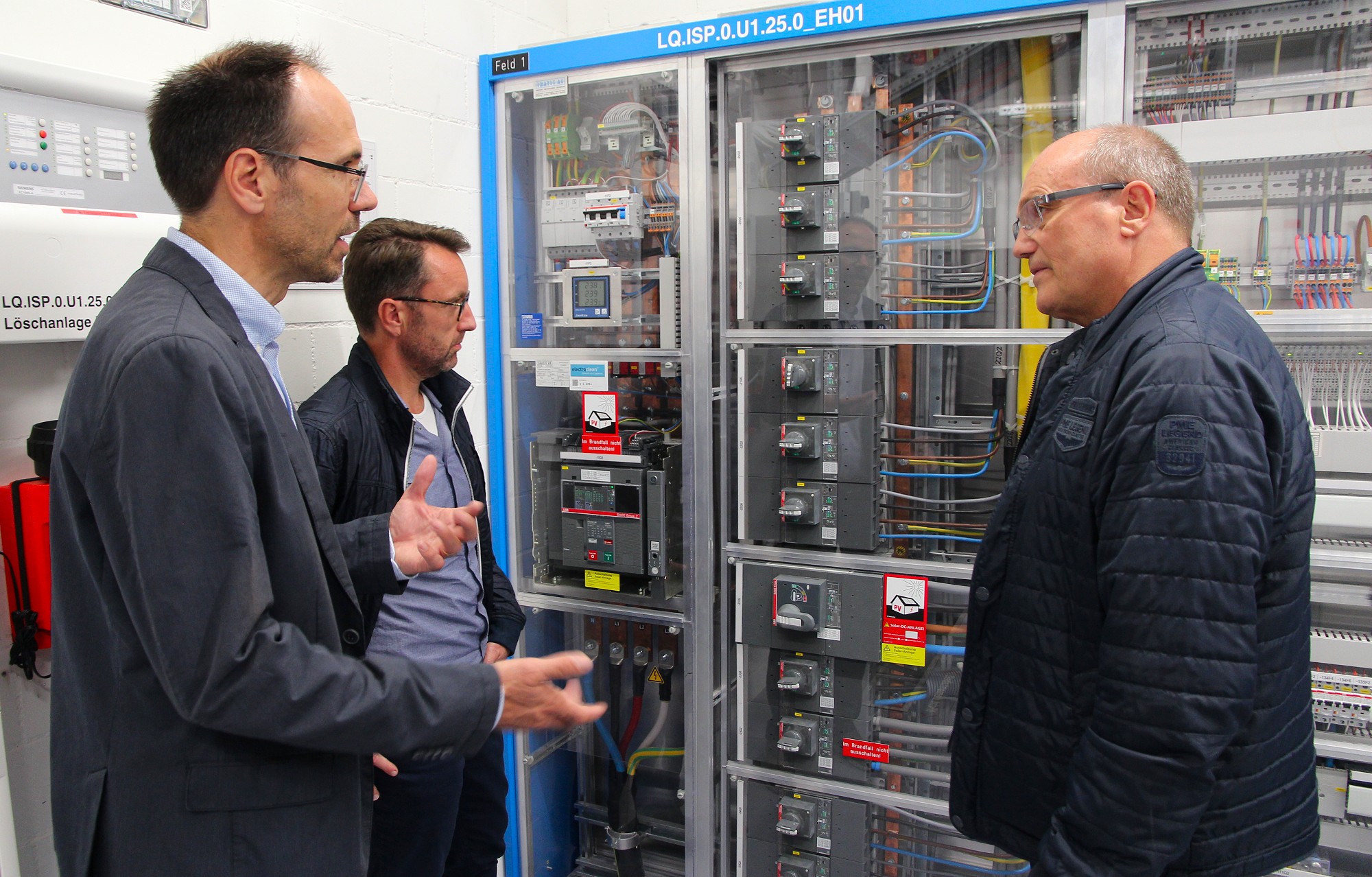

“We also began implementing a standardization strategy for the circuit breakers in our low-voltage distributors in 2020. We use ABB’s solutions for this,” Cotti adds. Quality was the main factor that drove this decision. The convenient size of the frequently used Tmax XT1 compact circuit breaker was another one of the ABB portfolio’s decisive advantages.

Fleet policy for circuit breakers

“The advantages of standardizing circuit breakers and sharing these specifications with electrical designers and switchgear system builders are obvious,” explains Cotti. “This ‘fleet policy’ simplifies both maintenance and documentation. We only need to keep a manageable number of circuit types as spare parts in stock. Service has definitely become much simpler and we were also able to standardize our technical documentation and schematics.” ABB is familiar with our installed base and can recommend custom-tailored maintenance measures – which can potentially extend the life cycle and, more importantly, make service calls more efficient.

For new systems, RhB provides ABB with a rough forecast on how many circuit breakers of which type it will need in the coming year. “That’s been about 50 to 100 units per year up to now,” explains Urs Schär, who works for ABB and is responsible for providing consulting to electrical designers. ABB uses this forecast to store the corresponding breakers in its local warehouse so that it can quickly deliver them when needed. “Each specific breaker has a unique order number that RhB or their system designers can use to procure them from us,” notes Schär.

System for uninterruptible power supply is also fed with traction current

At RhB’s Infrastructure Intervention Base, which was commissioned in 2020 and is located in the immediate vicinity of Landquart station, an ABB DPA 250 uninterruptible power supply (UPS) system will also ensure that the local IT infrastructure is protected against power failures and fluctuations. “We chose this solution based on its modular design. This UPS will grow with us if we require more power in the future.

One of the key features of this solution for RhB: The UPS is also supplied from the railway network via a 16 2/3 hertz module. This means that if the 50 hertz grid exhibits potentially damaging voltage and frequency fluctuations or even fails, the UPS can not only use the stored energy in the batteries as usual but can also supply the infrastructure connected to it via the traction power connection.

The partnership between RhB and ABB is entering its twelfth decade. Our company’s portfolio has changed and evolved over time – and so have our customers’ requirements. But what has remained the same is the cooperation built on trust and driven by the desire to produce increasingly efficient solutions based on their candid feedback.